Welcome To The Accelerator's Online Processing Symposium

It is said necessity is the mother of all invention and at this stage in our industry growers need low-cost, but effective processing lines...so growers have been searching high and low for suitable equipment.....or building it themselves. Below you will find photos and descriptions of processing equipment built, modified, or found by fellow growers. Want to share what you've learned, built, or found? Contact Jason Fischbach and he'll help you post the information on this page.

Custom Processors

Have a processing facility and offer custom processing? Contact Jason Fischbach to have information about your facility and services listed on this page.

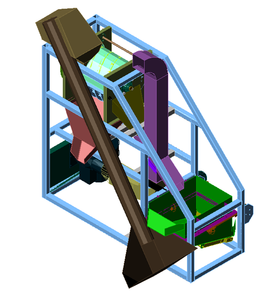

The Hazelnut Processing Accelerator Incubator - Ashland, WI

The Accelerator's incubator facility is a licensed food processing plant and can be accessed for processing per the terms and conditions of the Accelerator and partners. Contact Jason Fischbach for more information.

The Hazelnut Processing Accelerator Incubator - Ashland, WI

The Accelerator's incubator facility is a licensed food processing plant and can be accessed for processing per the terms and conditions of the Accelerator and partners. Contact Jason Fischbach for more information.